Pulse Jet Bag Filter

Al Meda Steel Factory offers advanced Pulse Jet Bag Filters, also known as Pulse Jet Hose Bag Type Filters, as a modern and innovative solution for conventional de-dusting filtration. Our redesigned filters deliver significant advantages, including extended filter bag lifespan, reduced emission levels, lower pressure drops, decreased power consumption, higher air-to-cloth ratios, improved performance, and a reduced floor space requirement.

Customization is a key aspect of our offerings, and we provide tailored bag filters based on specific application requirements. Pulse Jet Bag Filters find ideal use in scenarios with large airflows, elevated temperatures exceeding ambient levels, or handling challenging materials.

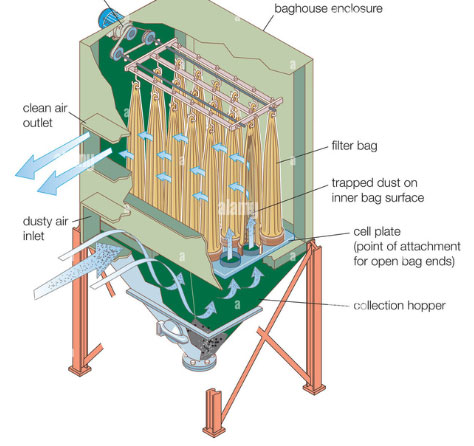

The concept of fabric filtration, which dates back over a century, remains relevant and highly practical for separating solids from air or gas streams. Tubular filter fabrics, both woven and non-woven, are widely adopted worldwide and installed vertically within a housing. To prevent vacuum or pressure-induced collapse, these bags are secured by metal cages fitted with venturis.

The dust cake accumulated on the filter bags is effectively cleaned row by row, either online or offline, through short-timed pulses of compressed air directed in the opposite direction of the primary airflow, originating from the clean air plenum. The integrated venturis on top of the cages enhance the cleaning air volume by inducing additional air from the top plenum, ensuring efficient and thorough cleaning.

Sequence Of Operational

- Dust laden air or gas enters the dust collector through the inlet.

- A signal from the timer actuates the opening of the normally closed solenoid valve.

- Opening of the solenoid valve release the air pressure in the tube

- Filtered air exits through the clean air plenum exhaust.

- Connecting the solenoid to the diaphragm valve, causing the valve to open.

- This momentary pulse takes all bags in one row off line through pressure reversal.

- Air passes through the filter media while solid are retained on the media's surface.

- Solids are released to fall into the filter hopper or bin