Our Facility

At our fabrication and machining shop facility, we specialize in providing high-quality solutions for heavy industrial fabrication and machining needs. With a strong commitment to precision, efficiency, and customer satisfaction, we have established ourselves as a trusted partner for diverse industries seeking reliable manufacturing services.

Our state-of-the-art facility is equipped with a comprehensive range of advanced machines and tools to handle complex fabrication and machining projects. Here are the essential machines you will find in our facility:

Our shop is equipped with a variety of welding machines such as MIG (Metal Inert Gas), TIG (Tungsten Inert Gas), and stick welders. These machines are capable of handling different types of materials, including steel, aluminum, and stainless steel, allowing us to perform high-quality welding for structural components and assemblies.

To manipulate and shape metal sheets, we have a range of hydraulic and mechanical presses as well as shearing machines. These machines provide the necessary force and precision to cut, bend, and shape metal sheets according to specific design requirements.

We have a selection of manual lathe machines for precision turning operations. These machines are instrumental in creating cylindrical components with tight tolerances, ensuring smooth surfaces and accurate dimensions.

Our milling machines, including vertical and horizontal mills, enable us to perform precise milling operations for the production of intricate parts, molds, and prototypes. These machines are essential for shaping materials with complex geometries.

We employ a range of grinding machines, such as surface grinders and cylindrical grinders, to achieve fine surface finishes and accurate dimensions on various metal components. These machines are crucial for achieving tight tolerances and meeting specific customer requirements.

Our facility is equipped with a diverse set of drilling machines, including radial arm drills, pillar drills, and magnetic drills. These machines ensure accurate hole drilling and tapping operations for various applications.

With CNC-controlled plasma cutting machines, we can accurately cut through various metal thicknesses, allowing us to create intricate shapes and profiles with speed and precision.

We have a dedicated quality control department equipped with advanced measuring instruments such as coordinate measuring machines (CMMs), gauges, micrometers, and other inspection tools. This ensures that all fabricated and machined parts meet the highest quality standards before they leave our facility.

To efficiently manage heavy fabrication and machining projects, we have invested in material handling equipment such as cranes, forklifts, and hoists. These enable us to handle large-scale components and optimize workflow throughout the manufacturing process.

almedasteel

Industrial Fabrication & Machining

At our fabrication and machining shop facility, we prioritize continuous improvement and stay up-to-date with the latest technologies and industry trends. Our experienced team of engineers, technicians, and skilled craftsmen work collaboratively to deliver superior fabrication and machining solutions that meet and exceed our clients’ expectations.

We are dedicated to providing outstanding customer service, on-time delivery, and competitive pricing, making us the preferred choice for heavy industrial fabrication and machining needs.

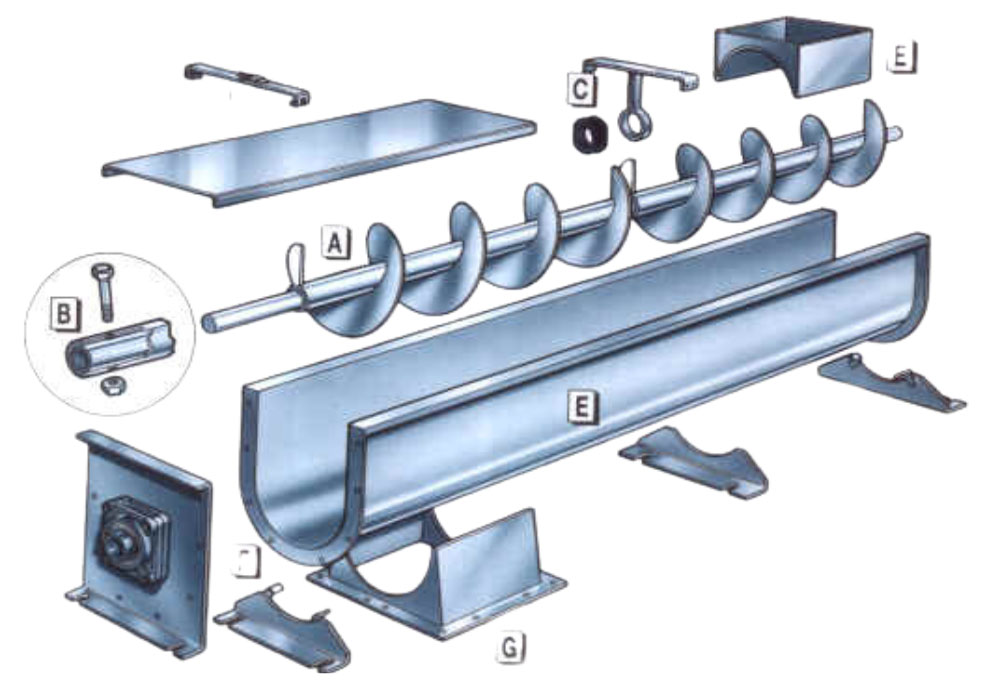

Screw Conveyor

Introducing Al Meda Steel’s new contract concept featuring the highly versatile “screw conveyor.” Widely used in various industries such as grain & oil, feed, food, metallurgy, mining, plastic, chemical engineering, building materials, and pharmaceuticals, this equipment efficiently conveys granular or powdered materials over horizontal, inclined, and vertical paths. With conveying lengths ranging from 2 to 70 meters and a diverse range of 120 to 600 specifications in carbon steel and stainless steel, we also offer custom options to meet your unique requirements.

Elevator Buckets

Damper Valve & Expansion Joint